Fascination About Mobile Sandblasting Adelaide

Rumored Buzz on Concrete Blasting Adelaide

Table of ContentsLittle Known Questions About Mobile Sandblasting Adelaide.An Unbiased View of Grit Blasting AdelaideThe 20-Second Trick For Concrete Blasting AdelaideThe Main Principles Of Sand Blasting Adealide What Does Sand Blasting Adealide Mean?The Main Principles Of Sand Blasting Adealide

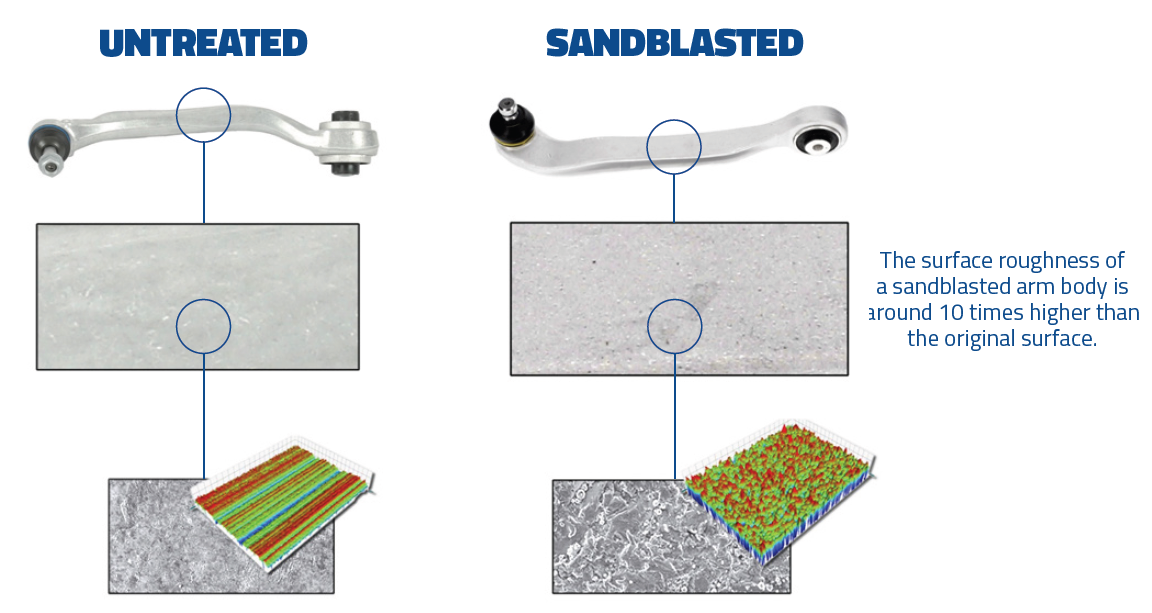

Without appropriate maintenance, our bridges and other infrastructure will proceed to wear away resulting in catastrophic failures in some instances. The concrete and also steel architectural members on bridges, overpasses, and also freeways need blasting to remove the old safety finish, allow evaluation, and permit revival or reapplication of protective coverings. Electronics/ Electric Micro rough blasters or mini blasters are an effective device for electronics repair.Sandblasting is phenomenal at the important step of cleaning as well as surface prep work before the application of coverings, adhesives, and also sealers. Sandblasting creates damages externally of a component, which enhances adhesion by enabling coverings and also adhesives to mechanically hold onto the surface. The finer sizes of blowing up media can be utilized to blow up clean and also prep inside holes, holes, as well as the detailed details of a component.

Depending upon the unpleasant or blast media utilized, sandblasting can be eco-friendly and also non-toxic. No damaging spent media are released when blowing up with completely dry ice, water ice, walnut shells, corn cobs, as well as soda. Usually, blast media can be reclaimed, separated, and also recycled several times, and also after that recycled.

6 Simple Techniques For Mobile Sandblasting Adelaide

Specific products such as lead-based paints and also hefty steels generate hazardous or harmful dust when blown up. In these applications, specialized vacuum cleaner blowing up systems or systems with high MERV purification is required to avoid the release of damaging products. Correct collection, handling, and disposal of the media are needed too.

The abrasive blowing up procedure breaks interior elements of sandblasting equipment. Media and palatable wear components need to be gaged to maintain consistency and afterwards repaired or replaced at ideal periods to guarantee quality and also safety and security. The expense of media and consumables need to be factored right into your sandblasting devices selection procedure.

Soda, dry ice, and also wet blasting maintain parts cool throughout blasting. Abrasives and blast media can obtain lodged into holes on a part and can be hard to eliminate. Start with the component size, form, as well as products in addition to the annual manufacturing volumes when taking into consideration the type of blowing up devices to pick.

Everything about Sand Blasting Adealide

While blast media price is one aspect, think about blast media efficiency, resilience, and also life. A much faster profile etching, cleaning, or stripping blast media is extra effective and reduces manufacturing times as well as throughput. Blast media that can be recovered and also reused for hundreds of cycles can have a reduced annual media price compared to a lower-cost blast media with a brief life or qualified of just a couple of reuse cycles.

How lots of operators pop over to these guys are needed to run the blast system? Send a quote for the blasting devices along with any added inquiries to make clear training as well as annual estimated operating, upkeep, and palatable prices.

Sand Blasting Adealide for Dummies

The primary benefit of rough blowing up is that the media made use of are inert, which implies that they do not respond chemically with the product being cleansed. Alternative techniques which make use of chemical cleansers risk of potential reaction as well as damages to the underlying product. These effects are not always right away observable, and problems can become apparent long after the surface area has actually been covered.

Provided, sandblasting does pose a health risk because of the fine dust as right here well as sand bits produced while doing so, yet drivers take safety steps to decrease the threat. o Unpleasant blasting is not just efficient for surface preparation, but it is also time and affordable. Grit Blasting Adelaide. State-of-the-art technology also offers mobile solutions for surface areas that are hard to reach to chemical and also handbook cleaning.

It can be utilized to remove corrosion, paint or scale from steel surface areas. The terms "sandblasting" and also "abrasive blowing up" are often used mutually.

All about Sandblasting Adelaide

Sandblasting, likewise understood as Abrasive Blasting is the procedure of blowing up unpleasant product at a surface area to smooth, rough up, tidy or get rid of layer.

Sand Blasting Adealide for Beginners

Since 2002, by law, we quit making use of silica sand, river sand, coastline sand, and also various other white sand consisting of over 1% crystalline silica for concerns of carcinogen from silicosis as well as cancer to workers and others around the worksite. Therefore, by the term sandblasting, Melbourne sectors have actually concerned understand blasting surface areas at high stress with much safer materials like garnet, glass grains, soda, steel grit, crushed glass, aluminium oxide, metal slag his response (with reduced degrees of chromium and also lead) and also also metal (steel) shots and granulated plastic.